Pallet

Safety and Regulations Pallets Can Be Dangerous If You’re Not Careful

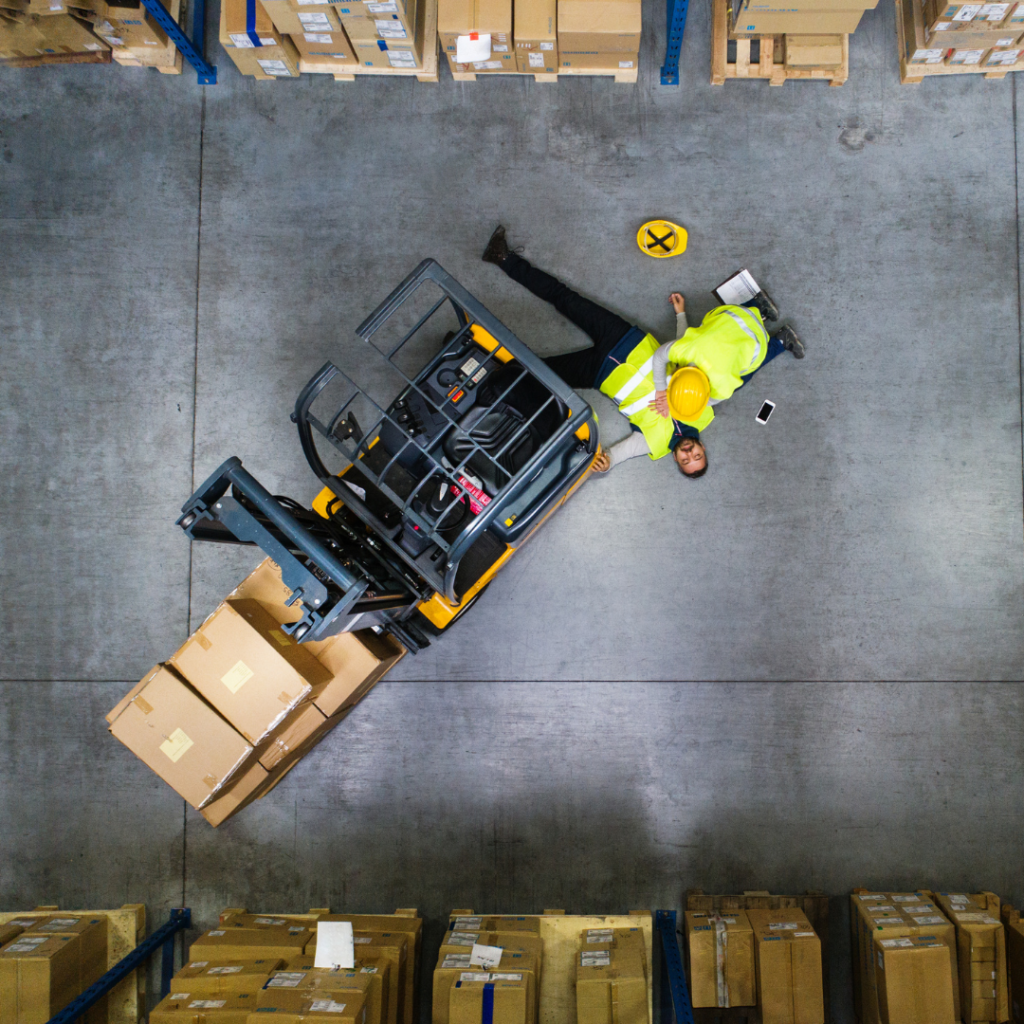

Pallets are a ubiquitous and often overlooked element of logistics and shipping. They are used to move and store everything from food and pharmaceuticals to industrial equipment and construction materials. However, working with pallets can be dangerous if proper precautions are not taken. In this article, we will explore how to make sure pallets are safe and the standards and regulations you need to know to stay compliant and minimize risks.

How Do You Make Sure Pallets Are Safe?

As a pallet supplier, JSX Lab understands the importance of pallet safety. Before delivering any wooden pallets, we ensure they are free from damage, such as broken boards, splinters, or protruding nails. This is crucial to prevent injuries when handling or stacking the pallets. It is also essential to inspect pallets for any evidence of contamination, such as dirt, chemicals, or pests, which can compromise the integrity of the goods they carry. All our pallet will got thought heat treatment (ISMP15) before we delivery.

Additionally, JSX Lab encourages customers to opt for plastic pallets or recycle pallets whenever possible. Plastic pallets are more durable and hygienic than wooden ones, while recycled pallets are eco-friendly and more affordable.

Read: Benefits and Disadvantages of Plastic Pallets You Need to Know

What Is the OSHA Standard on Pallets?

The Occupational Safety and Health Administration (OSHA) is a federal agency that sets and enforces safety standards in the workplace. OSHA has specific regulations related to pallet safety, which employers must comply with to protect their employees from hazards.

OSHA’s standard for pallets, 29 CFR 1910.176(b), mandates that employers stack and store pallets in a stable manner to prevent them from collapsing or falling. This includes stacking pallets on a level surface, securing them with appropriate restraints, and using appropriate lifting equipment to prevent damage to the pallets or injury to workers.

OSHA also requires that employers provide training to their workers on proper handling and storage of pallets. This includes instruction on how to recognize and report damaged or contaminated pallets, as well as how to safely stack and unstack pallets.

What Are the Standards for Pallet Stacking?

To ensure safe and efficient storage and transportation of goods, there are also industry standards for pallet stacking. The most widely recognized standard is the International Organization for Standardization (ISO) standard for pallets, which specifies the size, shape, and strength requirements of pallets.

In terms of stacking, there are several best practices to follow to ensure stability and safety. First, pallets should be stacked on a level surface, free from obstructions or debris. Second, they should be aligned and interlocked to prevent shifting or collapse. Third, they should be stacked no more than the recommended height, which varies depending on the size and weight of the goods being stored.

It is also important to consider the weight distribution of the pallets and the goods being transported. Heavier items should be placed on the lower tiers, and the load should be evenly distributed to prevent tipping or overloading.

Read: Pallets in Johor Bahru, Malaysia and Singapore

Conclusion

Working with pallets can be dangerous if proper precautions are not taken. As a pallet supplier, JSX Lab prioritizes the safety of its customers and encourages the use of plastic or recycled pallets whenever possible. To ensure compliance with OSHA regulations and industry standards, it is important to inspect pallets for damage and contamination, provide training to workers, and follow best practices for stacking and storing. By taking these steps, you can minimize the risks associated with pallets and keep your workers and goods safe.

whatsapp