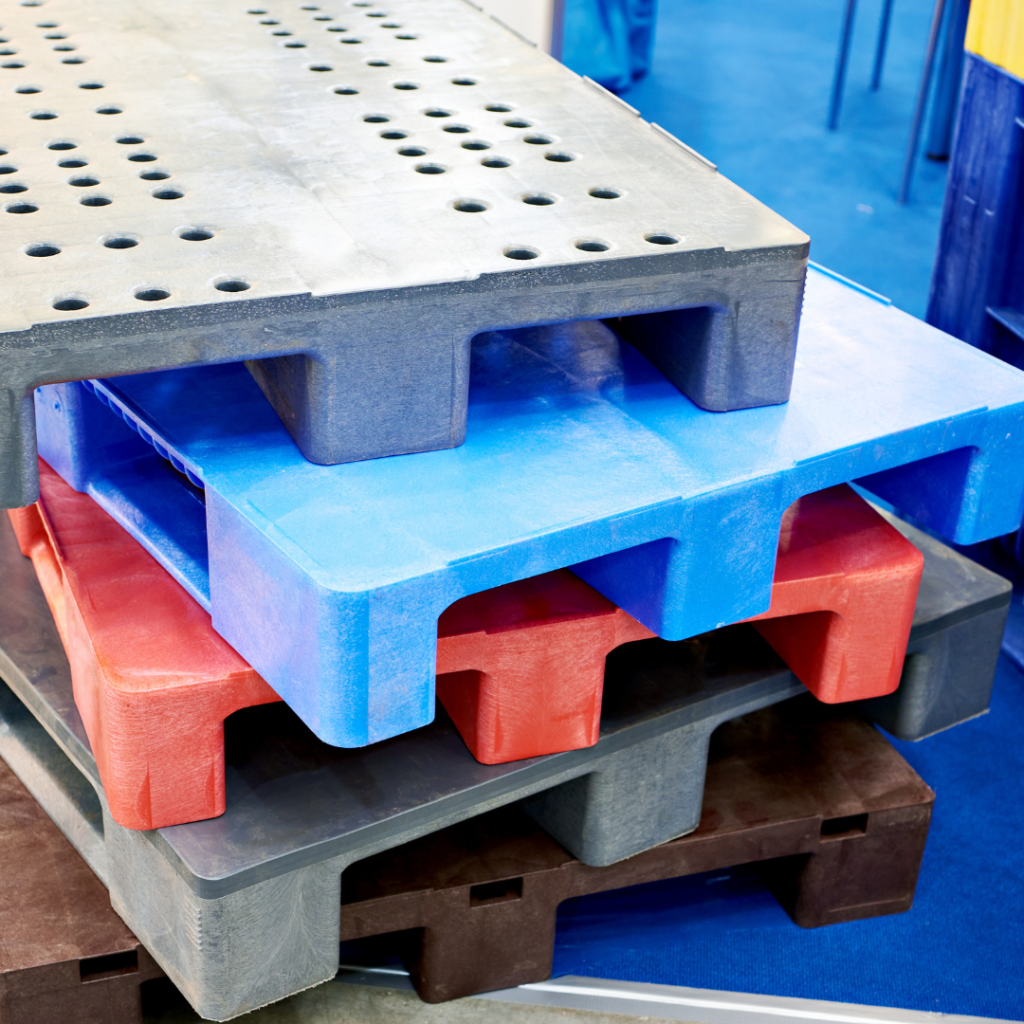

Pallet

You know The Manufacturing Process of Plastic Pallets

You know how plastic pallet is Manufacture. Plastic pallets can be made using many different techniques. Sometimes it can be difficult to determine which process will increase the company’s efficiency. Today’s most popular manufacturing techniques include injection, thermoforming, blowing, compression and Rotational molding.

We will be focusing on plastic pallet manufacturing by injection in this post. This is because JSX Lab is committed to providing the best quality products and supporting sustainability.

This article will describe the process and explain how it works. And there are six main steps to making a plastic pallet.

High-Pressure Injection Molding

These pallets can be made of copolymer polypropylene (HDPE) resin. A rotating screw rotates the rotating barrel to melt the plastic and colorant together. The melting temperature of the plastic is approximately 250 degrees Celsius.

The plastic is injected in a mold and then clamped under pressure. After the pallet cools, it can be ejected from its mold.

This process has one major drawback: It is expensive in terms of energy consumption.

Structural foam molding

This is an extremely low-pressure method of injection molding.

The melted polymer is infused with inert gas nitrogen or carbon dioxide.

This decreases the plastic’s density, resulting in a lighter product. The final product is made with a cellular core and surrounded by a stiff material.

Its weight could be as low as 10 to 30% compared to a solid plastic pallet.

Thermoforming

Thermoforming, a process that molds plastics over a long period of time, can make a precise mold. The vacuum suction presses thermoplastic sheets into single-face molds.

These pallets can be made quickly with simple or complex designs. You can make the pallet with CNC routers or automated rollers.

Twin-sheet thermoform pallets can be made from this process that are hollow inside. These pallets are lighter than traditional solid ones and much more affordable.

Rain and other liquids can enter the interior so it is important to use them in covered areas.

Compression molding

The cost-effective method of making new plastic pallets is compression molding.

It is less wasteful than injection molding, and it has lower tooling and labor cost.

The plastic material is heated in a mold, and then pressure is applied to ensure that it fills all the cavities and areas.

Keep the pressure on until the material dries. This process can be done with a variety of recycled materials such as rubber, plastics and synthetic resins.

Read: Do you know a 4 Way Pallet?

Rotational molding

The most popular product of rotational molding is the pallet.

The process starts with a powdered or granular material. This is then loaded into a mold. The mold is sealed and heated before being rotated on the two perpendicular axes.

The material spreads around the mold, fuses and then cools. Finally, it is ejected from the mold as a pallet shape.

This process uses both linear low-density and cross-linked high-density polyethylene (LLDPE),

Profile Extrusion

The profile extrusion method makes a pallet that looks like a wooden pallet.

The raw plastic is then melted and forced through an extruder. It is then cooled and cut into plank-like shapes. Finally, heat, nails, or welding are used to join the pieces.

This process has the advantage that it can be used recycled materials to lower costs. For extra rigidity, you can add wood fiber to the material.

Read: How to Made Wooden Pallets?

Conclusion

In this post we share How Are Plastic Pallets Manufactured. Plastic pallet manufacturing is a complex process that requires both high-pressure and low-pressure injection systems.

Over the years, the plastic injection has evolved towards smaller, quieter and more efficient machines. This is why JSX Lab selected this method to manufacture ours plastic pallets.

JSX Lab No.1 Wooden Pallet supplier in Malaysia Johor and Singapore.

We offer the best quality wood pallets, plastic pallets and plywood online at the best price to our Malaysia Johor Bahru and Singapore customers. Simply visit our Shop section to access our secure checkout. We offer a variety of standard New and recycling wooden pallets. These pallets are great for shipping and are also great for storage.

To speak with our team, you can call us at +6012 727 0188. Because we understand that each customer has a different budget, we work closely to find the best solution.

To learn more about our prices, request a quote today. Simply fill out the contact form to send us your details and specifications. We will get back to you as soon as possible with a custom price.

All JSX Lab pallets have been Heat Treated with ISPM 15 certified. You can browse our entire range of pallet sizes and types to find the right one for you. Secure delivery is available for all orders. We deliver to Singapore and Malaysia. If you need bulk orders or have questions, please feel free to contact our team.

whatsapp